Direct-to-Fabric (DTF) transfers have transformed specialty clothing design with their versatility and exceptional quality. This modern printing technique allows for intricate, detailed designs on various fabric surfaces, from vibrant graphics on t-shirts to elegant embroidery-like patterns on fine fabrics. DTF's adaptability enables application to diverse materials like cotton, polyester, and silk, giving designers complete freedom in creating unique clothing pieces. With high-definition printing that offers crisp images and vibrant colors lasting through multiple wash cycles, DTF is suitable for both fashion garments and durable outdoor wear. This technology streamlines production, reduces costs, and enhances customer satisfaction by enabling businesses to deliver personalized, high-quality garments quickly. Choosing the right materials, inks, and substrate compositions is crucial for achieving superior transfer quality. Incorporating DTF transfers opens up creative possibilities for designers, resulting in visually striking and tactily engaging garments. As demand for unique, personalized apparel grows, DTF technology is poised to remain a prominent force in shaping the future of garment production.

“Discover the revolutionary world of DTF (Direct to Fabric) transfers, a game-changer in the fashion industry. This cutting-edge technology allows for the precise application of designs onto specialty clothing, offering unparalleled versatility and customization. From understanding the core process to exploring creative design possibilities, this article delves into the benefits and trends shaping the future of DTF in garment production. Uncover why it’s a top choice for those seeking unique, personalized fashion pieces.”

- Understanding DTF Transfers and Their Versatility

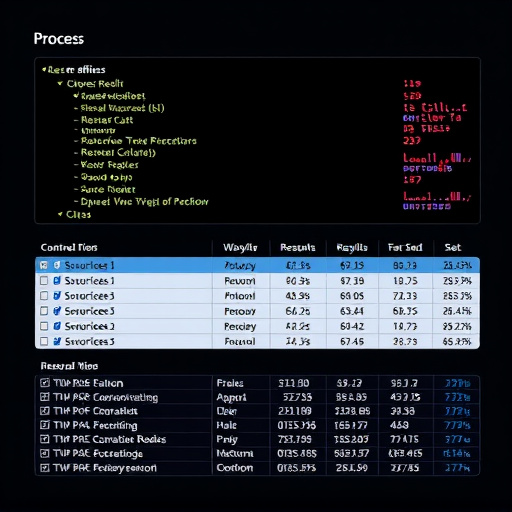

- The Process of Applying DTF Transfers to Specialty Clothing

- Benefits of Using DTF for Customization and Personalization

- Choosing the Right Materials for Optimal Transfer Quality

- Creative Ways to Incorporate DTF Transfers in Fashion Design

- Industry Trends and Future Prospects for DTF Technology in Garment Production

Understanding DTF Transfers and Their Versatility

DTF (Direct-to-Fabric) transfers have gained immense popularity in the realm of specialty clothing design due to their versatility and exceptional quality. This modern printing technique allows for intricate, detailed designs to be seamlessly integrated directly onto various fabric surfaces. From vibrant graphics on t-shirts to elegant embroidery-like patterns on fine fabrics, DTF transfers offer a game-changer for apparel creators.

One of the key advantages is their adaptability; these transfers can be applied to an extensive range of materials, including cotton, polyester, and even delicate silk. This versatility ensures that designers have complete freedom when it comes to creating unique clothing pieces. Moreover, DTF technology enables high-definition printing, resulting in crisp images and vibrant colors that withstand multiple wash cycles, making them ideal for both fashion-forward garments and durable outdoor wear.

The Process of Applying DTF Transfers to Specialty Clothing

The process of applying Direct-to-Fabric (DTF) transfers to specialty clothing involves several precise steps, ensuring a high-quality finish and long-lasting durability. It begins with designing the artwork or graphic using specialized software, allowing for intricate details and vibrant colors. Once the design is finalized, it’s printed onto a thin, flexible material known as a transfer paper using advanced printing techniques, often inkjet or laser printing.

The transfer paper is then carefully aligned and pressed onto the desired area of the specialty fabric. Heat and pressure are applied to fuse the inks from the transfer paper directly into the fabric fibers, creating a permanent bond. This method allows for complex designs and intricate patterns to be seamlessly integrated into various fabrics, making it popular for customizing clothing items like uniforms, athletic wear, and promotional merchandise.

Benefits of Using DTF for Customization and Personalization

Using Direct-to-Fabric (DTF) transfers for customization and personalization on specialty clothing items offers numerous advantages. One of the key benefits is the level of detail and precision it allows. DTF technology enables the application of intricate designs, graphics, and text with exceptional clarity and vibrancy. This makes it ideal for creating unique, personalized garments that cater to individual preferences and brand identities.

Additionally, DTF offers a fast and efficient method for customization. The direct printing process onto fabric eliminates the need for cutting and assembling pieces, reducing production time significantly. This streamlines the manufacturing process, making it cost-effective for small batches or custom orders. As a result, businesses can offer made-to-order clothing with customized designs in a timely manner, enhancing customer satisfaction and fostering brand loyalty.

Choosing the Right Materials for Optimal Transfer Quality

Choosing the right materials is paramount when designing transfers for specialty clothing items, aiming for optimal transfer quality. In the world of direct-to-garment (DTF) printing, the interaction between the transfer material, garment fabric, and ink plays a crucial role in determining the final outcome. For instance, selecting high-quality heat-transfer paper ensures crisp and vibrant colors that accurately represent the design, enhancing the overall aesthetic appeal. The substrate’s composition, such as polyestery or cotton, influences adhesion and durability, especially when catering to diverse garment types.

In terms of ink compatibility, DTF transfers demand specialized inks formulated for direct application on fabric. Water-based and solvent inks offer distinct advantages, each suiting specific applications. Water-based inks, known for their eco-friendliness, provide excellent color saturation and adhere well to a variety of fabrics. Solvent inks, while more volatile, deliver vibrant, lasting colors and are ideal for robust, outdoor garments. Ultimately, the material choice should align with the desired outcome, garment type, and end-use case to ensure a superior transfer quality that meets consumer expectations.

Creative Ways to Incorporate DTF Transfers in Fashion Design

Incorporating Direct-To-Fabric (DTF) transfers into fashion design offers a realm of creative possibilities for designers and artisans. One innovative approach is to use DTF on specialty clothing items, such as limited-edition jackets or custom-made dresses, creating unique, one-of-a-kind pieces. By employing intricate designs and vibrant colors, these transfers can transform ordinary fabrics into stunning works of art. For instance, a fashion designer might incorporate floral motifs or geometric patterns onto a silk blouse, adding an element of surprise and enhancing the overall aesthetic appeal.

Moreover, DTF technology allows for versatile design options. Designers can play with different materials, textures, and even mix media by combining transfers with embroidery or painting techniques. This versatility enables them to create pieces that are not only visually striking but also tactilely engaging. For example, a bold graphic print transfer on a denim jacket can be elevated further by adding hand-stitched details, resulting in a truly distinctive and personalized garment.

Industry Trends and Future Prospects for DTF Technology in Garment Production

The Direct to Fabric (DTF) technology has been gaining traction in the garment industry, marking a significant shift from traditional printing methods. This innovative approach allows for precise and efficient transfers on various fabric types, opening up new possibilities for designers and manufacturers. With its ability to produce high-quality, vibrant prints directly onto clothing, DTF is revolutionizing custom apparel and specialty items.

Looking ahead, the future of DTF technology appears promising, driven by the growing demand for unique, personalized garments. As consumer preferences continue to evolve, DTF’s versatility in handling complex designs and its capacity to reduce production time and costs make it an attractive option. Industry experts predict that further advancements will enhance the quality and longevity of printed fabrics, ensuring that DTF remains a prominent force in shaping the garment production landscape.